Identifying Common Issues with the OMRON CJ1 I/O Modules

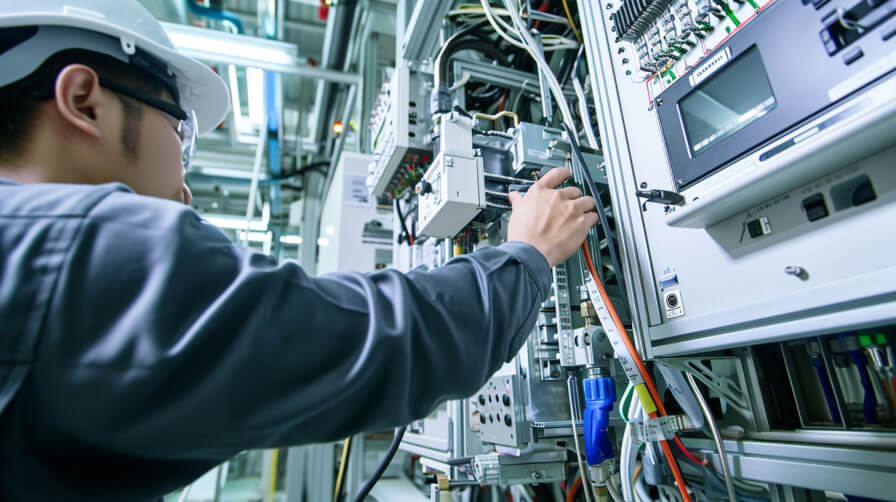

The OMRON CJ1 I/O modules are integral to controlling and monitoring various industrial processes. However, issues like communication failures, incorrect readings, or unresponsive modules can occur.

- Communication Glitches: These often manifest as error messages on the PLC or HMI, indicating a breakdown in the communication link between the module and the PLC.

- Incorrect or Fluctuating Readings: This can be due to sensor malfunctions, wiring issues, or incorrect configurations in the PLC program.

- Module Unresponsiveness: This could be a sign of power supply issues, internal faults, or configuration errors.

Step-by-Step Troubleshooting Process

- Initial Checks:

- Power Supply: Ensure the module is receiving the correct voltage.

- Physical Inspection: Look for visible signs of damage or loose connections.

- LED Status Indicators: These can provide immediate clues. For example, a blinking error LED might indicate a communication problem.

- Communication Checks:

- Cable Integrity: Inspect network cables for damage and ensure they are securely connected.

- Settings Verification: Confirm the communication settings (baud rate, node address) match those of the PLC.

- Software and Configuration:

- PLC Program: Check for any errors or misconfigurations in your PLC program that might affect the I/O module’s operation.

- Firmware Update: Ensure the module’s firmware is up to date.

- Advanced Diagnostics:

- Diagnostic Tools: Utilize OMRON’s software tools for advanced diagnostics. These can provide in-depth information about the module’s status and help pinpoint issues.

- Replacement or Repair:

- If all else fails, the module may need to be replaced or sent for professional repair.

Addressing I/O Bus Errors

- Understanding I/O Bus Errors in OMRON CJ1 Modules: I/O Bus errors often manifest as communication failures between the module and the PLC, leading to system malfunctions.

- Diagnostic Steps: Begin by checking the bus connections and ensuring all terminations are correctly made. Verify the integrity of the bus layout and confirm that all settings match the system requirements.

- Avoiding Common Pitfalls: Regular maintenance of the bus system and adherence to OMRON’s guidelines for bus layout and termination can prevent many of these issues.

Setting Addresses on OMRON PLCs

- Guide on Setting Addresses: Proper address configuration is key to ensuring seamless communication between the PLC and I/O modules.

- Importance of Correct Address Configuration: Incorrect addresses can lead to system failures or erratic behavior.

- Step-by-Step Address Setting:

- Access the PLC Configuration: Utilize the programming software to access the PLC system configuration.

- Identify the Module Slot: Determine the physical slot where the I/O module is installed.

- Assign the Address: Follow the software prompts to assign an address corresponding to the module’s slot.

- Verify and Save: Double-check the address settings for accuracy and save the configuration.

- Test the Configuration: Conduct a test run to ensure the system operates correctly with the new settings.

Best Practices for Preventing Future Issues

- Regular Maintenance: Regularly inspect and maintain your OMRON CJ1 modules. This includes checking connections, cleaning dust and debris, and monitoring for wear and tear.

- Training and Documentation: Ensure your team is well-trained in handling these modules. Keep documentation handy for quick reference during troubleshooting.

- Keep Spare Parts: Having spare modules and parts can significantly reduce downtime in case of failure.

- Software Updates: Regularly update the PLC and module firmware to ensure compatibility and smooth operation.

Conclusion

Troubleshooting OMRON CJ1 I/O modules efficiently requires a blend of technical knowledge, systematic approach, and sometimes, a bit of intuition. Remember, most problems can be resolved with thorough checks and basic corrective actions. For more complex issues, don’t hesitate to consult OMRON’s comprehensive manuals or reach out to their technical support team.

Stay informed, stay prepared, and you’ll master the art of troubleshooting, keeping your industrial processes running smoothly!

For more detailed guidance or technical support regarding Omron PLC issues, feel free to reach out to us at [info@ikwoco.com]. Our team of ikwoco engineers is always ready to assist you with your industrial automation needs.