Introduction to Omron PLCs

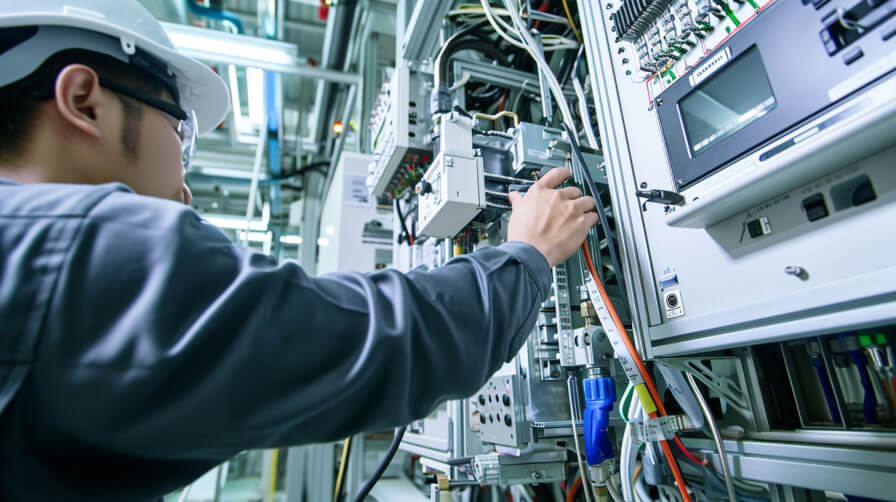

Omron PLCs stand out in the landscape of industrial automation for their robustness and advanced capabilities. Renowned for their reliability and adaptability, Omron PLCs are extensively used across a multitude of industries, including manufacturing, automotive, packaging, and pharmaceuticals.

These PLCs offer a range of functionalities suitable for both simple and complex automation tasks, making them a preferred choice for many industrial applications.

Purpose of the Article

This article aims to delve into the crucial aspects of preventing and addressing hardware failures in Omron PLCs. Hardware failures can lead to significant downtimes and operational losses, making their prevention and timely repair paramount.

We will explore practical insights into maintaining the health of these systems, ensuring their longevity and consistent performance.

Section 1: Understanding Omron PLC Hardware

Overview of Omron PLC Models and Their Hardware Components

Omron PLCs come in various models, each designed to cater to specific industrial needs. From compact models ideal for small-scale applications to more sophisticated systems for complex tasks, Omron offers a wide range of PLCs. Understanding the hardware components of these PLCs is the first step in ensuring their optimal operation.

Key Hardware Elements in Omron PLCs

The primary hardware elements of Omron PLCs include:

- CPU Units: The central processing unit, which acts as the brain of the PLC, executing control instructions and managing data.

- Power Supply Units: These units supply the necessary power to the PLC and its components, ensuring stable operations.

- I/O Units: Input/Output units are crucial for interfacing with external devices, sensors, and actuators, facilitating the real-time control and monitoring of various processes.

Common Hardware Specifications and Standards in Omron PLCs

Omron PLCs adhere to stringent hardware specifications and standards, ensuring high quality, durability, and compliance with international safety and operational norms. This adherence guarantees that these PLCs can withstand various industrial environments while providing reliable performance.

Section 2: Common Causes of Hardware Failures in Omron PLCs

Electrical Issues

- Overvoltage and Power Surges: These can cause immediate damage or gradual degradation of electronic components, leading to hardware failures.

Environmental Factors

- Temperature and Humidity: Extreme temperatures and humidity levels can adversely affect the electronic components, reducing their lifespan.

- Dust and Corrosive Substances: Accumulation of dust and exposure to corrosive substances can lead to hardware corrosion and malfunction.

Mechanical Stress and Vibration

- Continuous mechanical stress and vibrations, common in industrial settings, can lead to physical damage and misalignments in the hardware components.

Aging and Wear of Components

- Over time, components of PLCs can wear out due to continuous usage, necessitating regular checks and replacements to avoid unexpected failures.

Section 3: Preventive Measures to Avoid Hardware Failures

Regular Maintenance and Inspection Protocols

- Implementing a routine schedule for checking the physical condition, functionality, and performance of the PLC.

- Regularly updating and reviewing maintenance logs to identify any recurring issues or potential weak points in the system.

Proper Installation Practices

- Ensuring that all Omron PLC components are correctly grounded to prevent electrical interference and potential damage.

- Adhering to recommended wiring practices, avoiding overloading, and ensuring that all connections are secure and properly insulated.

- Implementing appropriate environmental controls, such as climate control in the PLC cabinet, to protect against temperature extremes, humidity, and dust.

Use of Protective Devices Against Power Surges and Electrical Noise

- Installing surge protectors and filters to shield the PLC from sudden power surges and electrical noise that can disrupt operations or damage components.

Firmware Updates and Managing Software-Hardware Compatibility

- Regularly checking for and applying firmware updates from Omron, which can resolve known bugs and enhance system performance.

- Ensuring compatibility between all software and hardware components of the PLC system to prevent conflicts and operational issues.

Section 4: Diagnosing Hardware Issues in Omron PLCs

Utilizing Built-in Diagnostic Tools and Indicators

- Leveraging the diagnostic capabilities built into Omron PLCs, such as LED indicators and onboard diagnostics, to quickly identify issues.

Reading and Interpreting Error Codes and Warning Lights

- Understanding the meaning of specific error codes and warning lights displayed by the PLC, which can provide initial clues to the nature of a problem.

Conducting Regular Performance Tests and Monitoring System Logs

- Regularly testing the performance and response of the PLC system to ensure it is operating within expected parameters.

- Reviewing system logs to detect anomalies or irregular patterns that could indicate underlying hardware issues.

Section 5: Repairing Hardware Failures in Omron PLCs

Step-by-Step Guide on Troubleshooting Common Hardware Problems

- Detailed instructions for diagnosing and resolving frequent hardware issues encountered in Omron PLCs.

Replacement of Defective Components

- Guidance on safely and effectively replacing common defective components such as relays, switches, and circuit boards.

Seeking Professional Repair Services vs. In-House Repairs

- Evaluating when to engage professional repair services versus handling repairs in-house, considering factors like complexity, cost, and equipment downtime.

Ensuring Safety and Compliance During Repair Processes

- Emphasizing the importance of following safety protocols and regulatory guidelines during repair processes to protect personnel and equipment.

Conclusion

In summary, the maintenance and adept handling of Omron PLCs are pivotal for the resilience and efficiency of industrial automation systems. From implementing preventive measures against hardware failures to mastering the nuances of diagnosing and repairing these sophisticated devices, every step is crucial. Ensuring the longevity and optimal performance of your Omron PLCs not only streamlines your operations but also fortifies the backbone of your industrial processes.

Don’t let the potential of your automation systems remain untapped. Elevate your industrial performance today by embracing the advanced solutions and expertise we offer in Omron PLC technology. Reach out to us [info@ikwoco.com] to discover how our services can transform your operational efficiency and reliability.