Empower Your Projects with Omron’s Elite Servo Range – Engineered for Exceptional Control and Durability in Industrial Applications

| Model number | Brand | Product Name | Specifications | Datasheet |

|---|---|---|---|---|

| R88D-1SAN02H-ECT | OMRON | Servo Drive | 1SA servo drive with safety, EtherCAT type, 200 W, 1~ 230 VAC | datasheet |

| R88D-1SAN08H-ECT | OMRON | Servo Drive | 1SA servo drive with safety, EtherCAT type, 800 W, 1~ 230 VAC | |

| R88D-1SAN15F-ECT | OMRON | Servo Drive | 1SA servo drive with safety, EtherCAT type, 1.5 kW, 3~ 400 VAC | |

| R88D-1SAN20F-ECT | OMRON | Servo Drive | 1SA servo drive with safety, EtherCAT type, 2 kW, 3~ 400 VAC | |

| R88D-1SN01H-ECT | OMRON | Servo Drive | 1S servo drive, EtherCAT type, 100 W, 1~ 230 VAC | |

| R88D-1SN04H-ECT | OMRON | Servo Drive | 1S servo drive, EtherCAT type, 400 W, 1~ 230 VAC | |

| R88D-1SN06F-ECT | OMRON | Servo Drive | 1S servo drive, EtherCAT type, 600 W, 3~ 400 VAC | |

| R88D-1SN10F-ECT | OMRON | Servo Drive | 1S servo drive, EtherCAT type, 1 kW, 3~ 400 VAC | |

| R88D-1SN15F-ECT | OMRON | Servo Drive | 1S servo drive, EtherCAT type, 1.5 kW, 3~ 400 VAC | |

| R88D-1SN15H-ECT | OMRON | Servo Drive | 1S servo drive, EtherCAT type, 1.5 kW, 1~ 230 VAC | |

| R88D-KN01H-ECT | OMRON | Servo Drive | G5 Series servo drive, EtherCAT type, 100 W, 1~ 200 VAC | |

| R88D-KN02H-ECT | OMRON | Servo Drive | G5 Series servo drive, EtherCAT type, 200 W, 1~ 200 VAC | |

| R88D-KN04H-ECT | OMRON | Servo Drive | G5 Series servo drive, EtherCAT type, 400 W, 1~ 200 VAC | |

| R88D-KN08H-ECT | OMRON | Servo Drive | G5 Series servo drive, EtherCAT type, 750 W, 1~ 200 VAC | |

| R88D-KN15F-ECT | OMRON | Servo Drive | G5 Series servo drive, EtherCAT type, 1500 W, 3~ 400 VAC | |

| R88M-1AL1K030C-BS2 | OMRON | Servomotor | 1SA AC servo motor, 1 kW, 400 VAC, 3000 rpm, 3.18 Nm, absolute encoder, with brake | |

| R88M-1AL1K030T-BS2 | OMRON | Servomotor | 1SA AC servo motor, 1 kW, 230 VAC, 3000 rpm, 3.18 Nm, absolute encoder, with brake |

Found a product or still searching? Send an inquiry today. Our team is ready to assist, ensuring you find the perfect Omron component for your project needs.

Only new, original OMRON products, ensuring reliability and superior performance for your projects.

Rapid, efficient shipping ensures your OMRON servos arrive when you need them, reducing downtime.

Providing comprehensive service worldwide, ensuring consistent support and availability for your automation needs.

With a vast stock spanning several OMRON servo series, we offer over 100 distinct models, ensuring immediate availability for your specific automation needs. Our range includes the latest and most in-demand servos, ready for swift global dispatch.

Offering 100+ OMRON servo models, catering to varied industrial automation requirements.

Immediate access to a large inventory, ensuring rapid delivery and minimal project delays.

Dedicated support team, ready to assist with every purchasing need.

Years of Experience

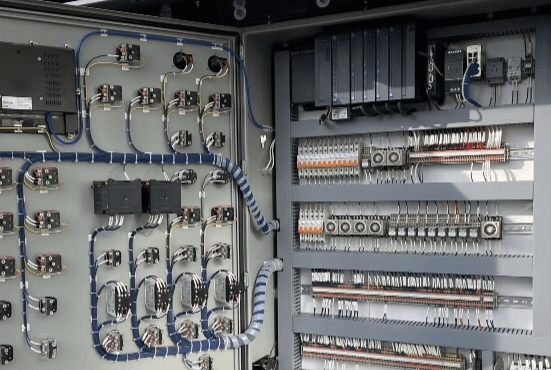

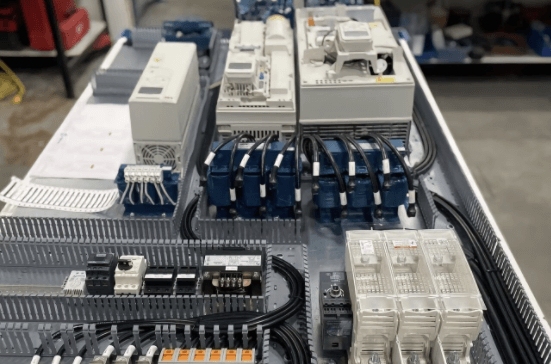

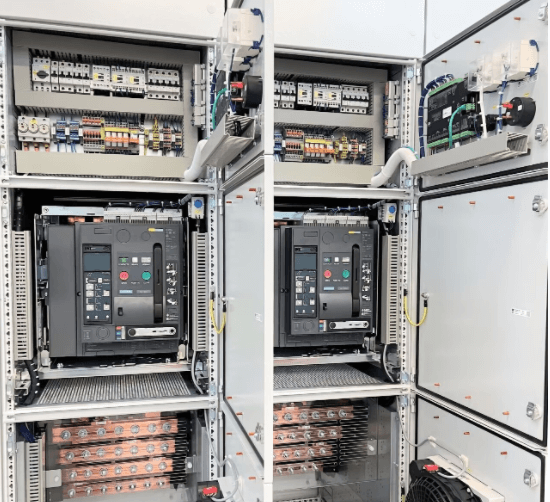

Versatile uses of OMRON servos in diverse engineering projects for enhanced efficiency and precision

Contact us now for expert guidance and swift integration of top-tier OMRON servos.

Experience unparalleled precision, efficiency, and reliability with our OMRON servo motors.

High Resolution and Speed: OMRON servo motors are equipped with a 20 bits high-resolution encoder and boast an EtherCAT communications cycle of just 125 µs.

Versatile and Powerful: These servos offer sizes from 50 W to 1.5 kW, with rated speeds of up to 3,000 rpm, and peak torque reaching 300% of continuous torque for at least 3 seconds depending on the model.

Advanced Control and Feedback: They provide sophisticated control over output torque, rotation speed, or position, with inputs from a motion controller, feedback encoder, and the servo motor itself.

Easy Integration and Safety: These servo drives and motors offer intuitive motion function blocks for easy programming and have built-in motion safety functionality.

SmartStep Technology: The SmartStep technology combines high performance with simplicity, offering features like on-line auto-tuning, easy setup, and electronic gear.

Overheating Signs: Check for mechanical binding, brake issues, or overloading. If these aren’t the problem, inspect the motor shaft for bearing failures and windings for signs of contamination or short-circuiting

Bearing Failure Symptoms: Listen for unusual noises or whining from the motor, indicating bearing issues. Prompt replacement is crucial to avoid complete motor failure.

Contamination Effects: Contamination leads to friction, underperformance, and grinding noises. Disassemble, clean, and reassemble the motor to resolve this issue.

Setup and Parameter Loss: Review the setup procedures of both the motor and connected drive. If issues persist, a feedback problem requiring repair might be present.

Power Output: Typically delivers lower power output, around 0.5 W to 100 W.

Speed Adaptability: Suited for high-speed operating conditions.

Torque: Capable of developing high torque.

Operation: Known for smooth, stable, and less noisy operation.

Efficiency: Generally less efficient, with efficiency ranging from 5% to 20%.

Stability: Less prone to stability issues.

Electronic Noise: Minimal electronic (radio frequency) noise.

Maintenance: Requires less maintenance.

Weight and Size: Relatively lighter and smaller in size.

Suitability: Ideal for low-power applications.

Applications: Commonly used in robotics, machine tools, semiconductor devices, aircraft, etc.

Power Output: Typically delivers lower power output, around 0.5 W to 100 W.

Speed Adaptability: Suited for high-speed operating conditions.

Torque: Capable of developing high torque.

Operation: Known for smooth, stable, and less noisy operation.

Efficiency: Generally less efficient, with efficiency ranging from 5% to 20%.

Stability: Less prone to stability issues.

Electronic Noise: Minimal electronic (radio frequency) noise.

Maintenance: Requires less maintenance.

Weight and Size: Relatively lighter and smaller in size.

Suitability: Ideal for low-power applications.

Applications: Commonly used in robotics, machine tools, semiconductor devices, aircraft, etc.

To select the appropriate OMRON servo motor for your application, follow these steps:

We provide comprehensive after-sales support, including technical assistance, warranty services, and prompt resolution of any issues you may encounter.

Our logistics team ensures fast and reliable delivery worldwide, with options for tracking and expedited shipping to meet your project deadlines.

We accept various payment methods including bank transfers, credit cards, and other secure payment options to accommodate your convenience.

Yes, we support small batch orders, allowing you to purchase the exact quantity you need for your specific project requirements.

Each product comes with a unique identification code that you can verify through Omron's official website to ensure its authenticity.

Reply within 24 hours

Omron PLC, HMI, Servo, Cables, Sensors, Relays… new original in stock.

B455, South Pearl Building, Sanlian Road, Longhua District, Shenzhen Guangdong, P.R.China.

info@ikwoco.com

Reply within 24 hours