Understanding the Basics

Before diving into troubleshooting, it’s important to understand that network connection problems in PLCs can arise from various sources, including hardware malfunctions, configuration errors, or network-related issues. Omron PLCs, known for their reliability and advanced features, are not immune to these challenges.

Step-by-Step Troubleshooting Guide

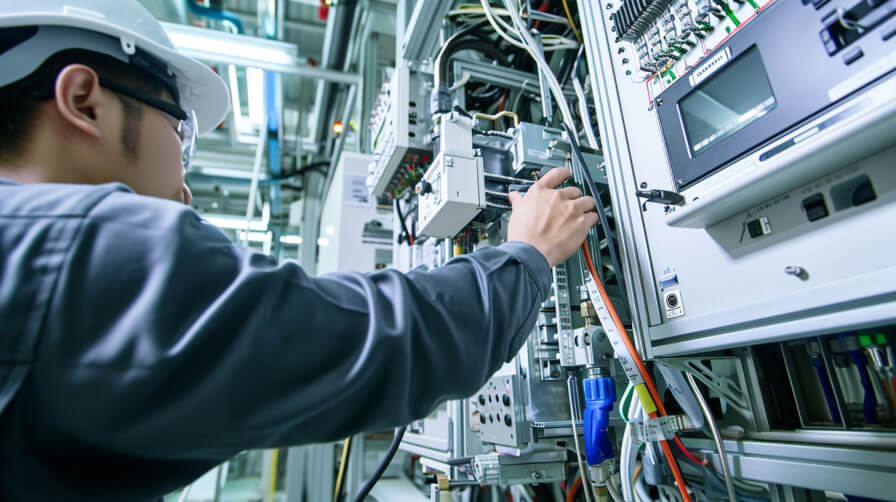

- Check Physical Connections: Start with the basics. Inspect all Ethernet cables, connectors, and ports. Ensure that cables are not damaged and are firmly connected.

- Verify Network Settings: Incorrect network settings are a common cause of connection issues. Check the IP address, subnet mask, and gateway settings in the PLC. These should match your network configuration.

- Inspect the Network Environment: Sometimes, the problem might not be with the PLC but with the network environment. Look for issues like IP address conflicts, defective routers or switches, and correct them.

- Update Firmware and Software: Ensure that your PLC and network devices are running on the latest firmware. Outdated firmware can lead to compatibility issues and other network problems.

- Utilize Diagnostic Tools: Omron PLCs come with diagnostic tools that can help identify network issues. Use these tools to monitor network traffic, check error logs, and understand where the connection is failing.

- Reset Network Parameters: If the above steps don’t resolve the issue, consider resetting the network parameters to their default settings and reconfigure them.

Advanced Troubleshooting

- Network Load Analysis: In complex networks, high traffic can cause connection problems. Analyze network load and consider segmenting the network to reduce traffic on specific channels.

- Hardware Inspection: Faulty hardware components can lead to connection failures. Inspect PLC components like Ethernet cards and replace them if necessary.

FAQ

1. What is the default IP address of Omron PLC?

The default IP address for Omron PLCs, such as the CJ2M model, is typically set to 192.168.250.1. This address allows the PLC to be identified and accessed within a network for initial setup and communication purposes.

2. What is the function of Omron PLC?

Omron Programmable Logic Controllers (PLCs) are primarily used in industrial automation for controlling machinery and processes. They read inputs from various sensors, process the data based on programmed logic, and then manage outputs to operate different industrial systems efficiently.

3. What protocol does Omron PLC use?

The Omron PLC uses several communication protocols, including FINS (Factory Interface Network Service) and Controller Link. FINS is a standard protocol by Omron for high-speed communication, which operates irrespective of specific protocol types. Controller Link, on the other hand, is an FA network that facilitates large volume data transmission between Omron PLCs and FA computers. This method supports both Data Link Function for constant data sharing and Message Service Function for transmitting data as required.

Conclusion

Network connection problems in Omron PLCs can range from simple to complex. By following a structured approach to troubleshooting, most issues can be resolved effectively. Remember, consistent maintenance and regular network audits can prevent many of these problems from occurring in the first place.

For more specialized advice, feel free to reach out with specific queries or share diagrams and schematics of your PLC setup for personalized assistance.

If you’re in need of immediate technical support or are looking to purchase genuine OMRON industrial automation products, feel free to contact us at info@ikwoco.com. With over 30 million worth of product inventory, our team at ikwoco is dedicated to providing quick quotations, delivery, and technical support for OMRON products.